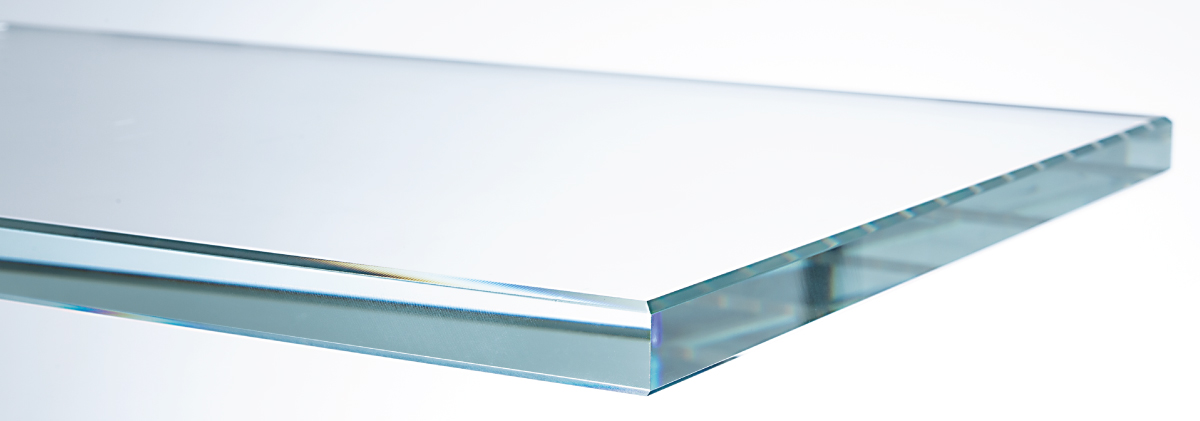

Monolithic Glass

Monolithic glass (i.e. glass that consists of a single ply), more commonly defined float glass, is a colourless glass that was launched on the market at the end of the 1950s. As the name suggests, it is made by “floating” molten glass on a bed of molten tin to produce a glass sheet. This is then cooled in controlled conditions to eliminate any inner tension. The floating process enables glass of uniform thickness to be produced that has flat surfaces and is colourless. Float glass is available in thicknesses ranging from 2 mm to 19 mm and is the basic material used in all subsequent glass processing operations.

The most commonly used thicknesses are:- For doors and windows: 4 - 5 - 6 mm.

- For "all glass" doors: 8 - 10 mm.

- For shower cubicles: 6 - 8 - 10 mm.

- For shelves, mantles and coffee tables: 6 - 8 - 10 mm.

- For table tops: 10 - 12 - 15 - 19 mm.

- For vanity unit tops and kitchen worktops: 10 - 12 - 15 mm.

Known as extra-clear, or erroneously as crystal*, this glass is practically colourless as it has undergone a special procedure to eliminate around 90% of the iron oxide. In order to produce extra-clear glass a selection of silica is made at the start of the process. This type of glass is more expensive, however it also gives superior aesthetic results due to its increased ability to convey light and outstanding results in terms of colour. This type of glass is popular in the medium- to high-end furnishing segment, especially when varnished, enamelled or screen-printed, precisely because of its superb colour and contrast effects.

*N.B.: Crystal glass (or simply crystal) has a lead content of up to 35% and is used for the creation of artistic objects such as highly valuable glasses. It is harder but also more fragile than other types of glass and is appreciated mainly because of its superb brilliance. Bohemia Crystal is crystal glass to which potash has been added.